Increasing demands of comfortable living conditions and healthy global environment have been giving more pressures to the wastewater treatment technology. Maezawa has been improving wastewater treatment technologies through all experiences in the field over 50 long years. We have been aggressively cooperating with technology leaders outside of Japan, while taking every public requirement as ours to continue the accumulation of new technology.

The wastewater treatment system is one of the most featured technologies of Maezawa, based on user-friendly technology, in which local conditions, treatment quantity, economic efficiency and environmental standard such as BOD, SS and COD are fully reflected.

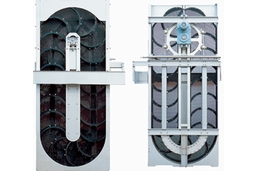

The Pin-Rack Screen Unit is designed for easy operation and maintenance as well as to reduce lead times for construction. Based on long-time practical experience in designing and manufacturing of equipment for sedimentation basin, Pin-Rack Screen Unit from Maezawa can respond to the increasing demand of equipment renewal in many respects.

Features:

Easy installation and Maintenance

Simple structure with few components

Metal parts protection

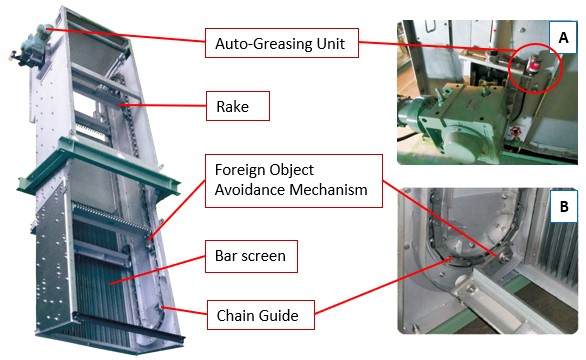

Chain type screen unit is ideal for combined sewers. With minimal components, it surpasses continuous belt secreens in durability, even in high-sand condition. Our innovative foreign object avoiding mechanism proactively prevents damage, making it resilient against substantial sand or large foreign objects.

Features:

Protective with foreign object avoiding mechanism

Easy maintenance and installation

Simple structure with few components

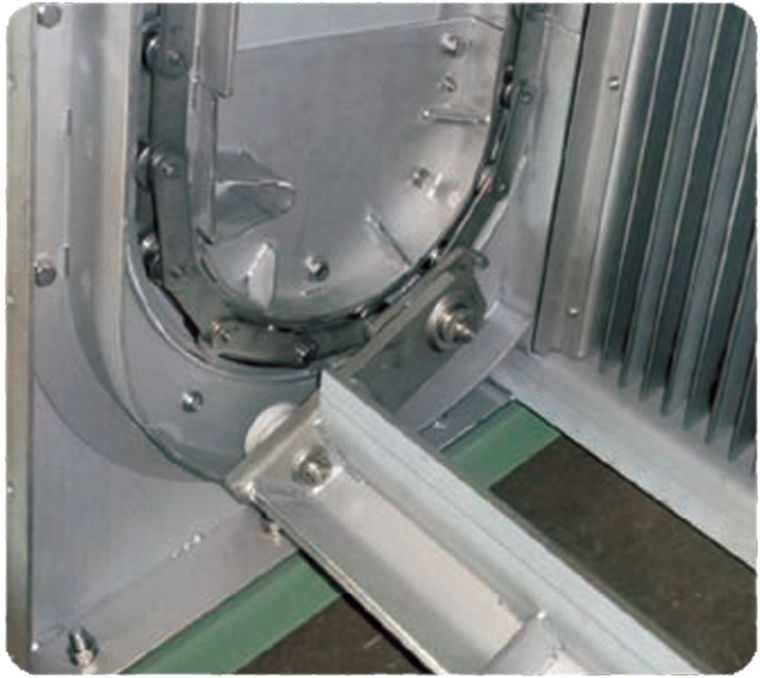

➤ Protective

with foreign object avoiding mechanism

The conventional chain type screen may breakdown if large foreign objects get trapped, as the fixed rake can experience excessive load. Our Foreign Avoidance Mechanism prevents this issue by allowing the rake to dissengage from the chain's path when overloaded, then returning to its path once the obstruction passes.

➤ Easy Installation

Installation

Delivered as pre-assembled unit with all necessary components.

- Eliminates the time

- Cost saving

- Avoiding unexpected assembly failures

➤ Easy Maintenance

Lubrication is designed to only two points with Auto-Greasing Units (A) for the drive bearings. The absence of sprockets and bearings in the underwater section, lubrication at the channel bottom (B) is unnecessary.

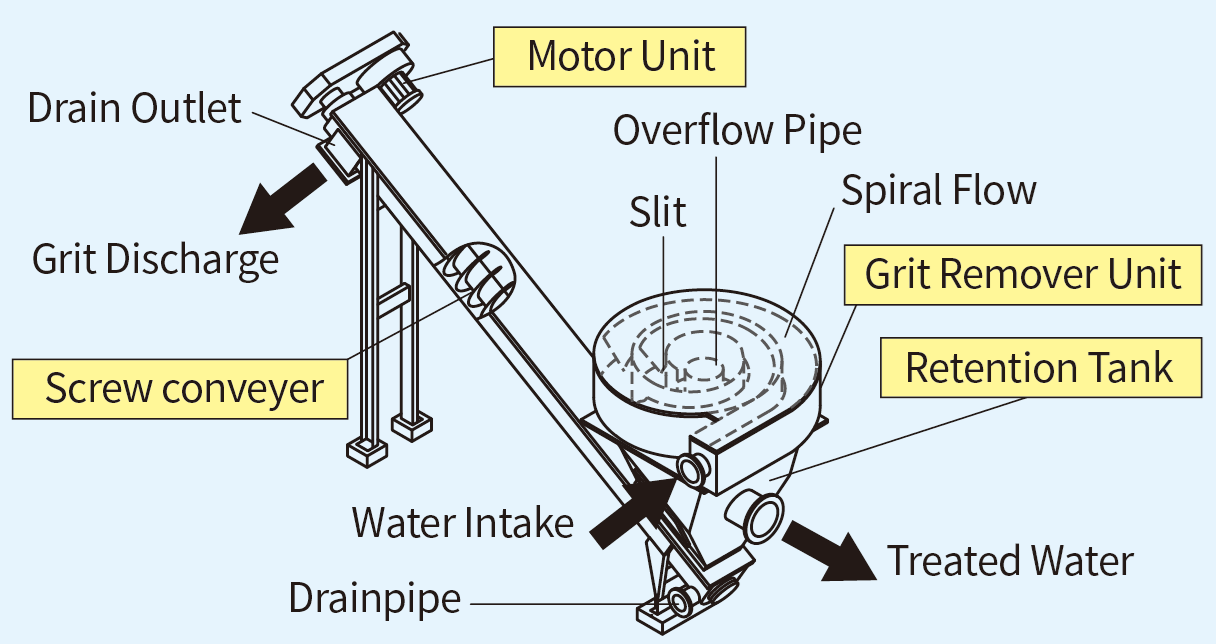

Escargot is the grit remover originally designed by Maezawa Industries, inc. Escargot ensures grit separation with the helical screw system and will eliminate roll up and short pass of grit which has been a major problem with conventional grit chambers.

Features:

The original helical structure ensures the reliable separation of grit and water.

Concentrating grit in the retention tank allows for a smaller screw conveyor diameter and energy savings.

➤ Structure and Function

- In the grit remover unit, by making the flow path spiral with its special design, a large inflow passage cross-sectional area and a long flow path length can be obtained, resulting in ideal sedimentation conditions with minimum short path.

- Settled particles fall through slits located at the bottom of the helical flow channel and are collected in the retention tank.

- After grit removal, the treated wastewater overflows the center of the tank.

- The grit accumulated in the retention tank is dewatered and conveyed by a screw conveyor, then discharged through the chute.

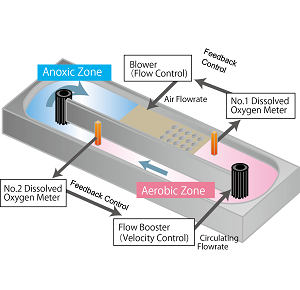

Dual DO control for OD system enables efficient and stable nitrogen removal by controlling aeration and water circulation independently, and producing optimal aerobic and anoxic zones.

Features:

Low power consumption

Efficient and stable nitrogen removal

MBR (Membrane BioReactor) produces highly purified water with smaller foot prints. PTFE hollow fiber with high mechanical strength and chemical resistance enables a longer period of stable operation and higher durability for heavy duty operation than membranes made of other types of resins.

LANDOX OD System is a new Oxidation Ditch system composed of LANDOX - high efficiency flow booster and the fine bubble air diffuser. It is a suitable solution for renewal of an aeration system using vertical drum mixers, which especially leads to energy saving and improvement of nutrient removal. The system also accommodates deep ditch (Approx. 5m depth) where efficient propulsion of the mixed liquor is required.

MMS is a unique screen that removes fine debris by circulating mesh panels that are connected to revolving chain at their rear side. These basis and structure lead to higher removal rate of fine debris and maintainability than conventional automatic screens.